Condensate Management in Compressed Air Systems

All compressed air systems create condensate. Because the ambient air naturally contains moisture, condensate (the liquid formed by compressing the ambient moisture) is an inevitable by-product that can build up in the compressed air system.

Demand Drains – Zero Loss

Zero loss drains help save money by conserving compressed air. To limit air loss, ASP zero loss drains remove collected condensate automatically and on-demand without loss of compressed air. Up to 30% of electricity consumed by a manufacturing facility can be attributed to compressed air usage. Due to leaks, artificial demand, and inappropriate use, the manufacturing floor can waste as much as half of the compressed air produced.

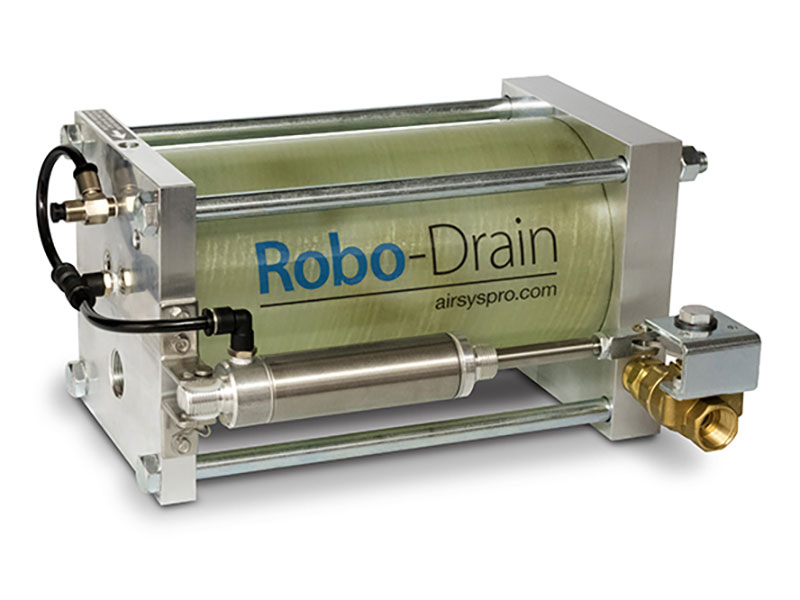

Robo-Drain RD11-T

most commonly purchased condensate drain

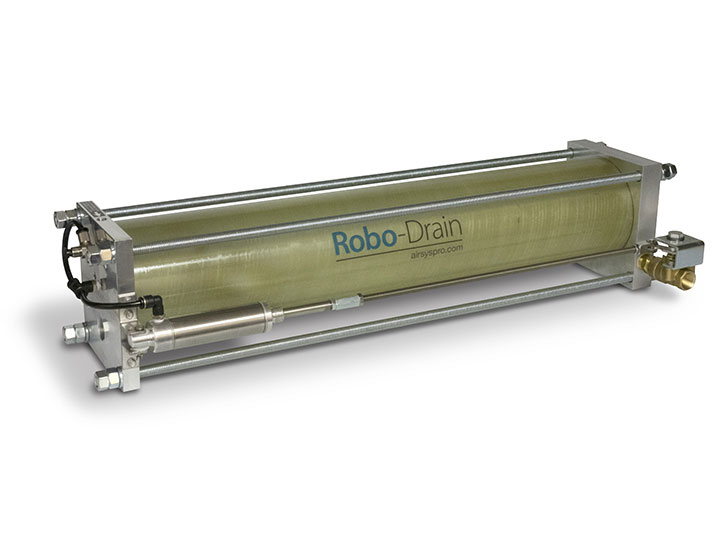

Robo-Drain RD13

Our condensate drain with increased capacity

Robo-Drain RD750

A condensate drain for high pressure compressors

Robo-Vac

A condensate drain for vacuum systems

Accu-Drain

A zero-loss condensate drain that uses an electric plug

EZ-Drain

A condensate drain that requires no utilities

Dehydra

Vertical Zero-Loss Drain that takes up less floor footprint

Timer Drains

Timer operated drains are reliable, cost-effective devices that open the drain’s valve periodically and for an adjustable period of time. The valve may be open for a few seconds once an hour to remove the collected condensate. Time drains are appropriate in smaller systems or applications where the condensate generated is low.

dDV720 Series

An electric timer drain with digital, programmable screen

Posi-Drain

A premium timer drain with straight flow and a gate valve

Sure Drain – Solenoid Valve

Uses a conventional diaphragm valve

BVD – Ball Valve

Non-clogging and designed to handle higher flow

Oil / Water Separators

Oil/Water Separators are specifically designed for compressor condensate and to bring discharges into compliance with environmental regulations. Provisions of the Clean Water Act prohibit the discharge of oil-laden condensate to surface waters, sanitary sewers, or wastewater treatment plants. As a result, ASP has developed a wealth of application knowledge on treating the different types of compressor lube oils.

Accu-Zorb

Can simultaneously process multiple types of oil

Accu-Zorb 7

Designed for smaller compressed air systems

Accu-Sep

Ideal for applications that require multi-stage separations

Posi-Zorb

Handles a variety of oils, cleaner condensate discharge

Equalizer

designed to collect and manage high volumes of condensate for multiple oil/water separators

Oil / Water Separator Replacement Media Kits

Changing your media is surprisingly simple. Whether you’re utilizing our Accu-Zorb, Accu-Sep, or Posi-Zorb OWS system, the process to change out the media is just a few short and simple steps.

Accu-Zorb Media

Replacement media and filters for the Accu-Zorb line of OWS Systems

Accu-Sep Media

Replacement media and filters for the Accu-Sep line of OWS Systems

Posi-Zorb

Replacement modules for the Posi-Zorb line of OWS Systems

Condensate shortens the lifespan of a compressed air system and results in the loss of productivity, and increased maintenance costs. Condensate also includes a small amount of compressor lubricants along with scale, corrosion, metal particles and rust. This can result in substantial maintenance costs, operational downtime and loss of productivity.

Moisture can create many issues in a compressed air Air System Products, LLC. (ASP) is a leading manufacturer of condensate drains and oil/water separators for the air and gas compressor market. As a manufacturer, we are able to advise, service, and custom engineer many variations of our standard products. Our growth and valued reputation is a result of our continued introduction of innovative and reliable products coupled with our strong after sales support. ASP is also the leading distributor of miniBOOSTER hydraulic intensifiers in North America.

Want more information on managing condensate in your compressed air system?

Complete the form to receive 3 free E-Books: The Cost of Compressed Air, The Importance of Condensate Drains, and Responsible Condensate Management