Accu-Sep

Oil / Water Separator for Air Compressor drains

Designed with multi-stage separations for real-world, 24 hour continuous operation. Sized and designed to operate in most ambient conditions year-round. No electricity required.

Features

- Constructed of all non-corrosive materials

- Gravity activation

- Diffuser has multiple inlets, the entire assembly can be rotated

- Removable access lid

- Translucent oil container collects de-emulsified oil

- Red flow indicator

- Sample and reference jars

Benefits

- Easily maintained with low maintenance costs

- No electricity required – no moving parts

- Makes installation more convenient

- Easy entry to the Pre-Adsorption Chamber and the Carbon Media

- Can be easily monitored

- A visual alert that service is required

- Quick evaluation of the clean condensate,ensures proper operation

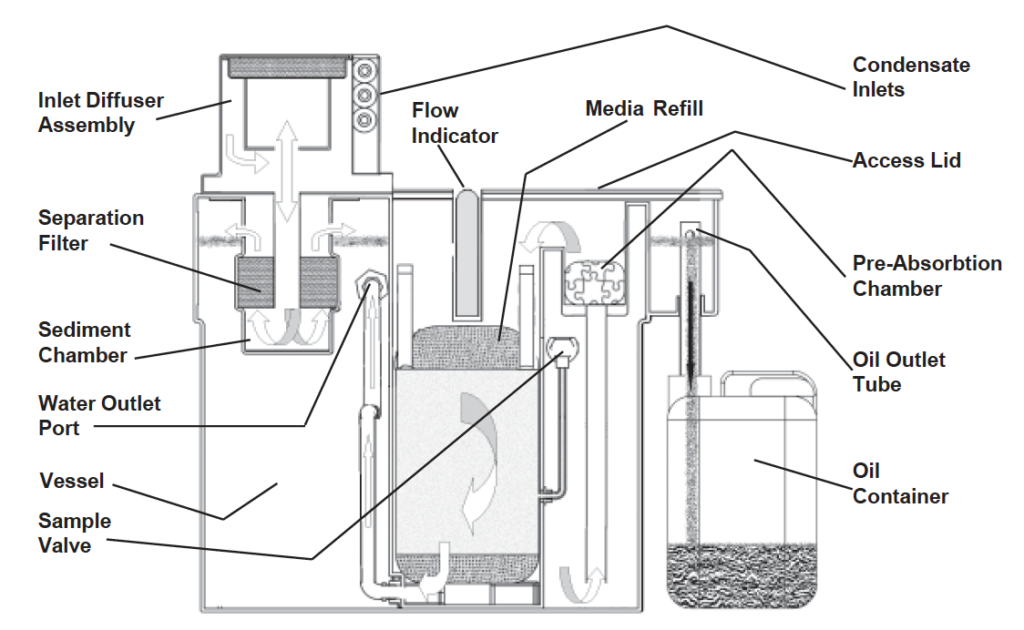

How it Separates Oil and Water from Air Compressor Drains

The Accu-Sep utilizes multi-stage separations technology to remove lubricating oils from condensate streams. In the first stage, the sediment chamber collects and helps prevent rust, dirt, and scale from migrating into the main reservoir. The second stage is the large main reservoir, which provides sufficient residence time to allow oil to coagulate and float to the surface. Next, the pre-adsorption chamber removes the segment of oils that are still in the solution or have migrated through to this chamber. In the final stage, the carbon beds ensure that the condensate will meet or exceed the discharge limits.

Specifications / Dimensions

| Stock No. | Max. CFM Capacity* (90°F/90%RH) | Height | Depth | Width | Dry Weight (lbs.) |

| AS15 | 150 | 30″ | 19″ | 26.5″ | 50 |

| AS30 | 300 | 39″ | 21″ | 34″ | 90 |

| AS60 | 600 | 39″ | 31″ | 35″ | 170 |

| AS120 | 1200 | 39″ | 31″ | 72″ | 240 |

| AS180 | 1800 | 39″ | 31″ | 109″ | 360 |

| AS240 | 2400 | 39″ | 31″ | 146″ | 480 |

Diagram

Support and Downloads

Accu-Sep Installation Operating Manual

Want more information on managing condensate in your compressed air system?

Complete the form to receive 3 free E-Books: The Cost of Compressed Air, The Importance of Condensate Drains, and Responsible Condensate Management

Related Products

Robo-Drain RD11-T

most commonly purchased condensate drain

dDVT720 Series

An electric timer drain with digital, programmable screen

Accu-Zorb

Can simultaneously process multiple types of oil

Posi-Zorb

Handles a variety of oils, cleaner condensate discharge